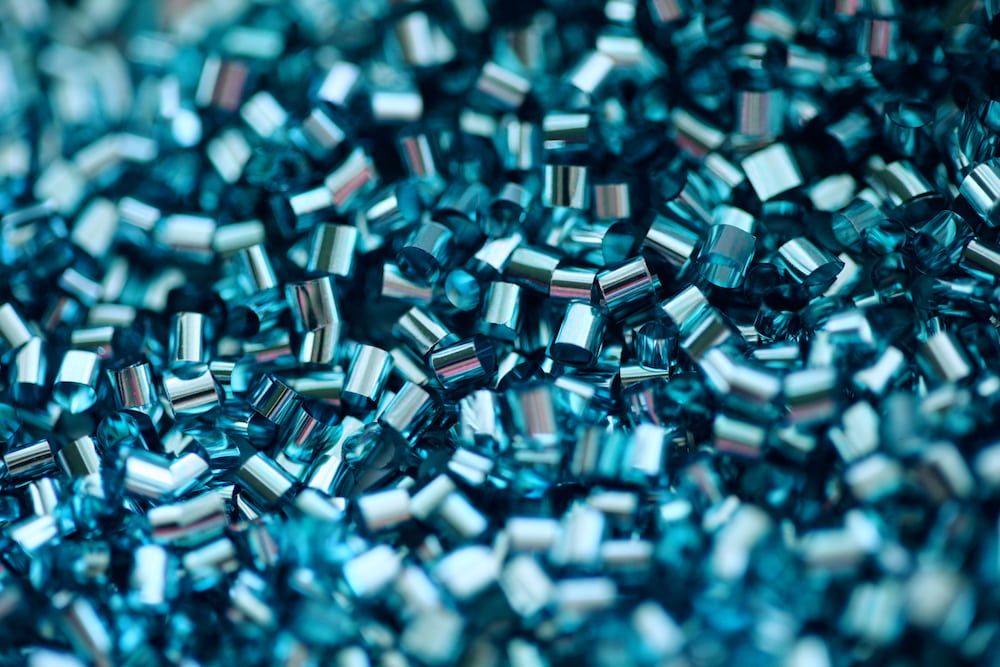

The second “green” direction, which has been used in metallurgy for a long time, is the production of semifinished products for subsequent steelmaking by direct reduction of iron from high-iron raw materials by special technologies (Midrex, Arex, Hyl, etc.). The output is the so-called metallized raw material – hot-briquetted iron (HBI), metallized pellets DRI (Direct Reduced Iron), sponge iron. This is a metal product with a high iron content, up to 99%, which can be used immediately in the steelmaking process to produce steel. Today, such direct reduction iron is the mainstay of electric steel production as a substitute for scrap and other iron-containing ingredients. This technology has been developing for more than 30 years. To a greater or lesser degree, its efficiency has been proven, but this technology requires either initially high-purity ore material – iron ore with high iron content and low impurities – or large energy capacities.

That’s why such lines are located in Brazil, Australia in the mining areas where very good ore is available, and in the Middle East, where cheap gas is in abundance, which is used to recover iron from iron-containing raw materials.

Today, direct reduction technology is at its peak and is one of the most advanced and widely used.