Metallurgy has always played a key role in ensuring national security. The production of steel and alloys is not just the foundation of heavy industry but also a crucial element in the chain of creating modern weapons, armored vehicles, aviation, and naval fleets. Steel forms the “skeleton” of defense — from the bodies of combat …

Recent Posts

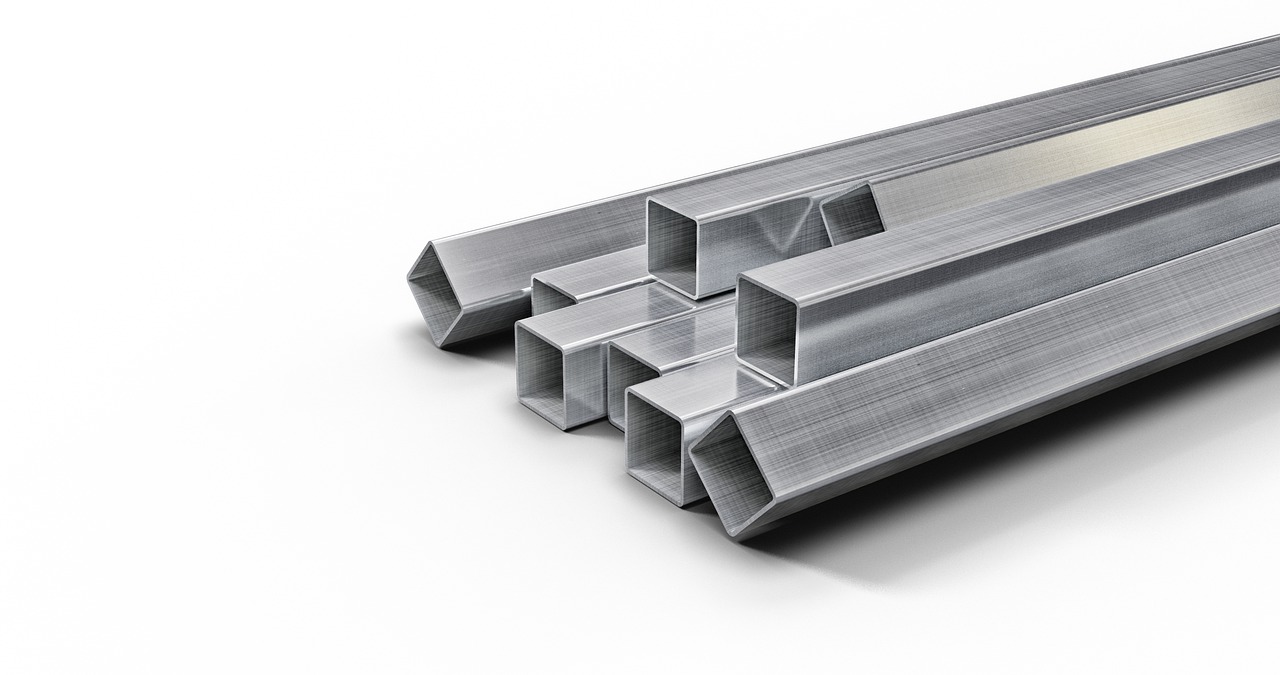

Combined smelting and rolling processes

Speaking of metal smelting, it is worth noting that combined smelting and rolling processes are becoming increasingly widespread. A melting unit – a converter or electric furnace – is installed in one shop, continuous casting takes place on a continuous casting machine, from which only solidified hot slabs, blooms or billets go directly to rolling. …

Oxygen-converter and electric steelmaking processes

If we talk about modern steelmaking technologies, the key ones are the oxygen-converter and electric steelmaking processes. The martensky method of steelmaking is used less and less in the global metallurgy. And this is largely due to “green ecology” again. As is known, the open-hearth smelting process takes 9 hours, while the converter and electric …

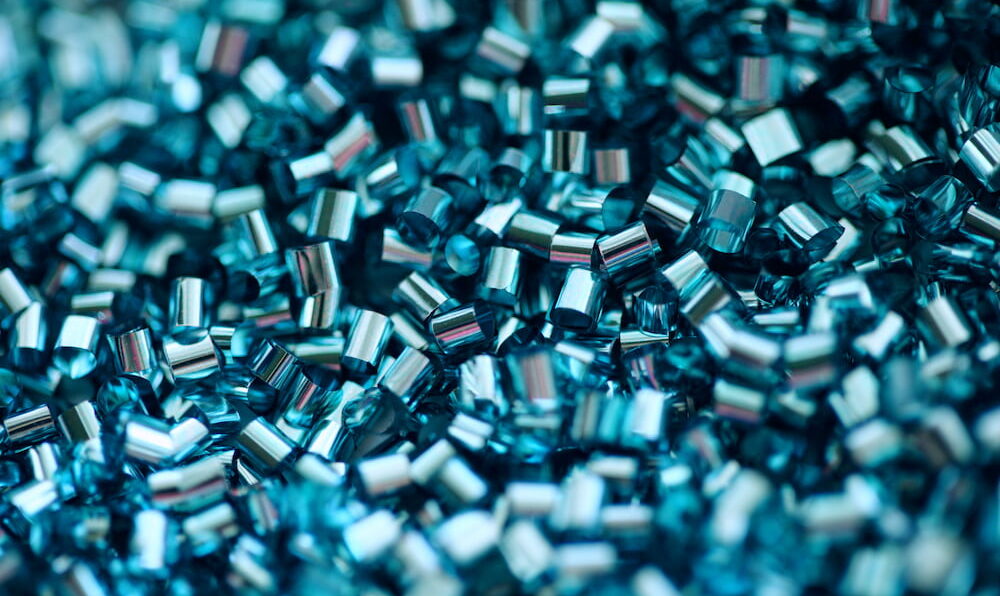

Direct reduction of iron

The second “green” direction, which has been used in metallurgy for a long time, is the production of semifinished products for subsequent steelmaking by direct reduction of iron from high-iron raw materials by special technologies (Midrex, Arex, Hyl, etc.). The output is the so-called metallized raw material – hot-briquetted iron (HBI), metallized pellets DRI (Direct …

Hydrogen versus carbon

It is no longer necessary to prove to anyone the need to switch to “green steel production,” which is intended to make the production process more environmentally friendly. There are several directions in this direction. The first of these is now considered the most promising – the abandonment of carbon in favor of hydrogen. The …

Trends in global metallurgy

Metallurgy is actually not as conservative an industry as is commonly believed, and it is not lagging behind other industries in following major global trends. The main emphasis today is on “green steel production. This will enable the industry to withstand environmental problems and regulatory pressure. The growing demand for high-quality steel grades will require …